Freeze drying is the drying of frozen food in vacuum, below the triple point. The vacuum allows the freeze-drying process to be carried out, facilitating the direct conversion of ice into steam, without any intermediate liquid stage. This leads to the most gentle drying process, preserving the shape, color, taste and nutrients of the product.

After freeze-drying, the products retain their organoleptic properties — shape, size, taste, color and flavor. The beneficial biological components of the product are also preserved. The minimum weight of the final product facilitates transportation and warehouse manipulations, and also significantly simplifies the requirements for long-term storage.

We offer innovative equipment and comprehensive solutions for drying any products with the use of the freeze-drying method — this is a modern technological solution that will allow you to discover new markets and provide them with a high-quality freeze-dried products

Our technological solutions for shock freezing are a key element in the field of food canning. This freezing method is a process in which products are subjected to intensive cooling at very low temperatures in the shortest possible time. As a result of this process, the natural taste and nutritional qualities of the products are maintained, as well as their texture and color.

Shock freezing helps increasing the shelf life of products, keeping them fresh and safe for the consumer. The natural taste and nutritional qualities of the products, their texture and color are also preserved.

We offer our customers innovative solutions that cover the entire process of creating frozen products, starting with the preparation of raw materials and ending with packaging. The equipment is designed to ensure the maximum productivity, quality and shelf life of frozen products. Our experience and advanced technologies will increase the efficiency of your production.

Our technological solutions and equipment for production of canned food are highly efficient systems designed to meet the diverse needs of food manufacturers.

The method of product canning keeps the natural taste and nutritional properties of product and prevents the development of microorganisms in it. Canning also protects the product from destruction under the influence of high temperatures and sunlight.

Technical solutions will ensure accurate and efficient canning, while maintaining the natural taste, nutritional properties of products and high quality standards. We offer a wide range of equipment, including machines for cutting, processing, packaging and canning of various products such as vegetables, fruits, fish and meat.

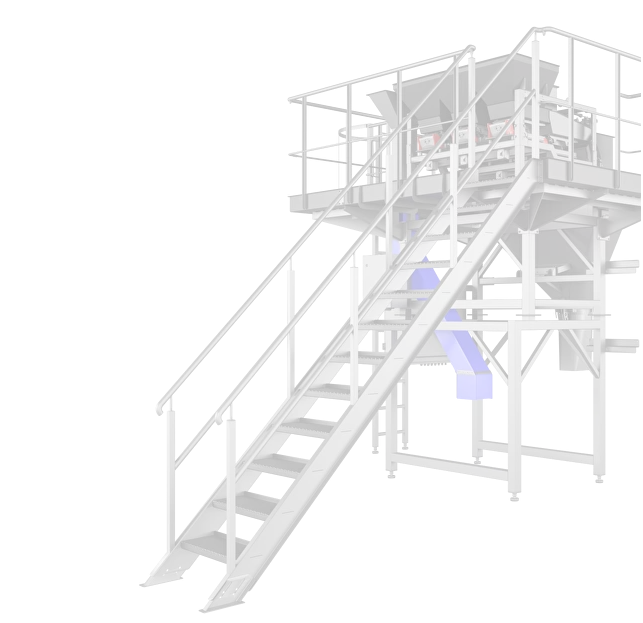

Packaging production lines are specialized equipment that is used in the final stage of the production of goods for everyday consumption or technical purposes. They are designed for fast and high-quality packaging of products, providing protection of goods from atmospheric influences and damage during transportation and storage.

The method of product canning keeps the natural taste and nutritional properties of product and prevents the development of microorganisms in it. Canning also protects the product from destruction under the influence of high temperatures and sunlight.

We offer innovative packaging equipment designed to increase production efficiency, reduce costs and ensure reliable protection of your goods at every stage of their movement and storage.

Installation of technological equipment is an important stage in the creation of efficient production systems. We specialize in professional installation of a variety of equipment, from production lines to installation of machines and systems for product processing, packaging and control. We strive to provide our customers with ready-to-use equipment that will help them achieve optimal performance and product quality.

Our company pays special attention to the level of qualification of employees, as well as compliance with Safety and Labor Protection Requirements during the performance of work. Every year, the company's employees undergo specialized training, improve their qualifications and pass certification. Only high-quality and certified tools, equipment and materials are used when performing installation and welding work.

We perform high-quality installation, taking into account all technical requirements of Customers. Due to advanced management and process planning, the facility is launched within the established time frames. Internal quality control will ensure reliable and stable operation of the equipment, which will allow you to make the most of its capabilities.

By clicking the button, you confirm that you agree to the user agreement and are familiar with the Privacy Policy

We call you.